Lee Laim

Innovation Manager, Micron

Meg Hermes

User Reference Manager, JMP

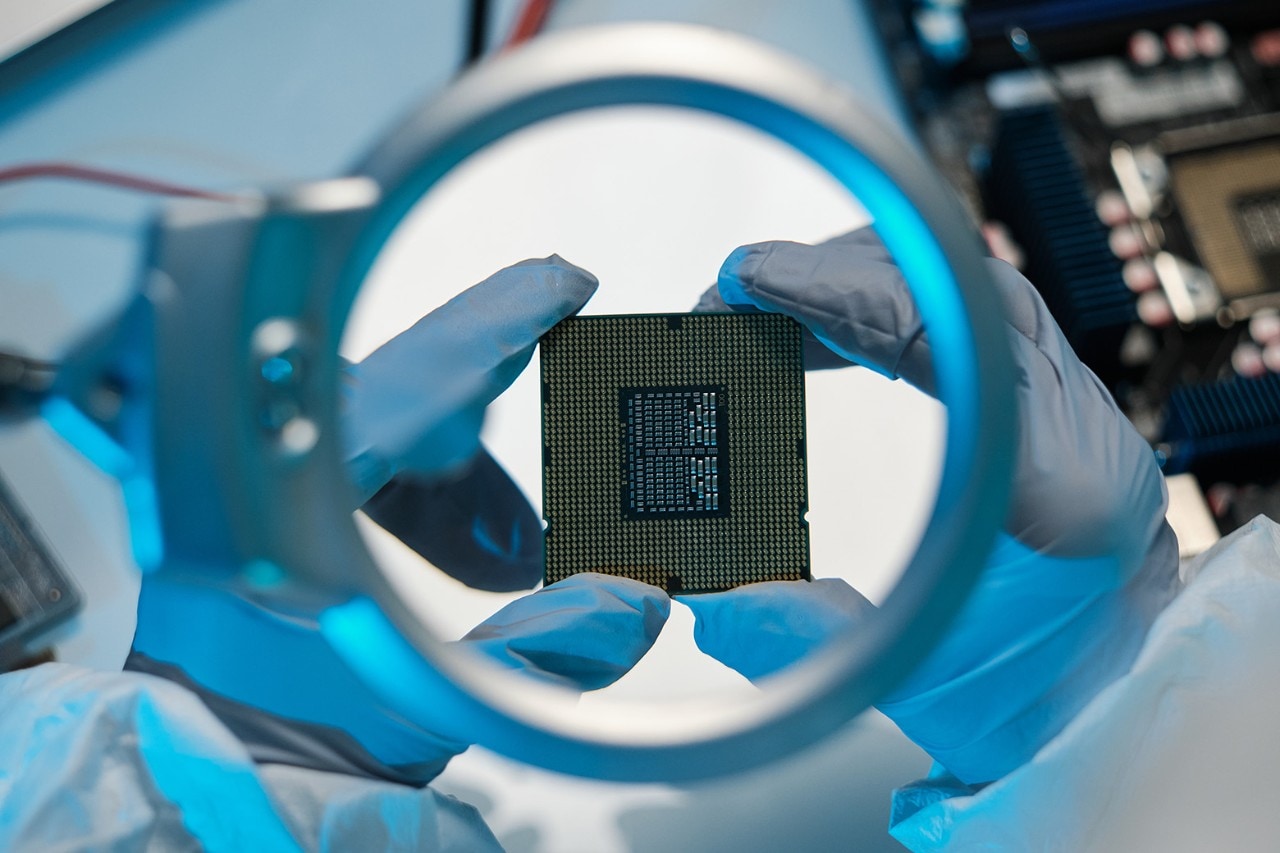

Lee Laim began his career at Micron Technology more than 14 years ago. Starting as a semiconductor yield engineer, he worked to monitor reliability and post-assembly yields on the production of dynamic random access memory (DRAM) products, flag yield limiting process deviations and perform electrical characterization and fault isolation. Embracing industrial statistics early on, Lee quickly rose through the ranks to become Innovation Manager.

Today, he is responsible for implementing the company’s analytics vision via Industry 4.0 initiatives that drive quality improvements and cost savings at every stage of the manufacturing workflow.

Though his background is in semiconductor engineering and spectroscopy, Lee has become adept at statistical analysis, data mining and machine learning – all of which he says complement domain expertise at Micron.

JMP User Reference Manager Meg Hermes sat down to talk with @leelaim about the role he’s played at Micron in advocating for the deployment of statistical approaches.

Meg: You first joined Micron as a yield engineer, likely with not all that much experience in industrial statistics – at least comparatively speaking! But fast forward 14 years, and you’re in a role devoted entirely to analytics transformation and Industry 4.0. How would you say your enthusiasm for analytics has shaped your career path so far?

Lee: The amount of data we collect requires constant innovation in data storage, retrieval and analytics. I feel like my current role as Innovation Manager is a direct result of relentless focus on connecting data to the business needs in my previous roles. Knowing how the data is generated, collected and stored is one-third of the battle; another third is knowing how to access, refine and interpret the data; and the final third is being able to share the insights with the larger network.

Meg: What a great point about drawing a direct line between data and business needs – that’s really the essence of analytics culture: getting people to think about how they can use data to solve business challenges. What kinds of successes have helped you to sustain momentum for this kind of thinking?

Lee: Improvements around simplifying data accessibility for more users through APIs has made it easier to get ideas off the ground and into production.

Meg: What is the value in having a workforce of engineers and scientists who, in addition to being domain experts, are also statistically literate? Has JMP in any way changed how domain experts at Micron apply their knowledge and skills?

Lee: Domain expertise and statistical approaches complement each other at Micron. Domain experts will always have the upper hand in abstract thinking, while the computer is unrivaled in its ability to churn through massive amounts of data. JMP is a platform that allows our domain experts to code their insights to deploy on large data sets, leading to greater impact in less time.

Meg: JMP offers a lot different resources for learning and engaging with other users – I’m thinking about things like the Early Adopter program and Discovery Summit. In your experience, what value do you get from participating in these kinds of programs?

Lee: With the Early Adopter program, we get to learn about new functionality in upcoming releases. We also get to see different ways of using existing platforms. For example, using images as markers in the Graph Builder provides an intuitive dimension to the analytics.

Meg: What advice would you give to someone looking to cultivate a more mature analytics culture in their organization?

Lee: Analytic vision has to be driven from the top. Alignment of platforms, methods, and training enables faster development cycles.

Meg: How about advice for someone who’s just starting out with JMP?

Lee: It takes some time to understand how the different data types affect different analytic platforms. Once data types are understood, use the scripting and statistics index to learn and apply analytics to your data sets.