Nelson (1982) discusses the failure times of a small electrical appliance that has a number of causes of failure. One group (Group 2) of the data is represented in the JMP sample data table Appliance.jmp.

|

1.

|

|

2.

|

Select Analyze > Reliability and Survival > Survival.

|

|

3.

|

|

4.

|

Click OK.

|

|

5.

|

From the red triangle menu, select Competing Causes.

|

|

6.

|

|

7.

|

Figure 13.12 shows the Fit Y by X plot of Time Cycles by Cause Code with the Quantiles option in effect. This plot further illustrates how the alphas and betas relate to the failure distribution.

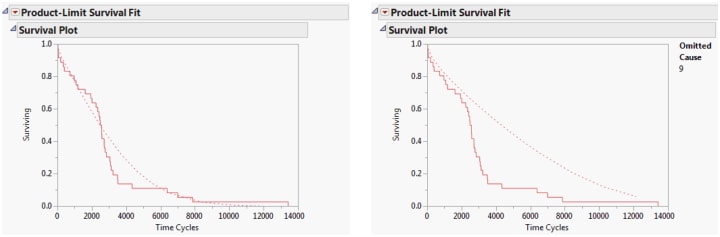

In this example, recall that cause 9 was the source of most of the failures. If cause 9 was corrected, how would that affect the survival due to the remaining causes? Select the Omit Causes option to remove a cause value and recalculate the survival estimates.

Figure 13.13 shows the survival plots with all competing causes and without cause 9. You can see that the survival rate (represented by the dashed line) without cause 9 does not improve much until 2,000 cycles. It then becomes much better and remains improved, even after 10,000 cycles.