Create and Assess the ALT Design

After entering you accelerated life test (ALT) specification, click Make Design to create an optimal ALT design. A balanced design is provided for comparison. There is a design report and a design diagnostic report to use for evaluating your ALT design.

Note: By default, the optimal design is quantile estimate optimal. To change the optimality criterion click the Accelerated Life Test Plan red triangle and select ALT Optimality Criterion.

Review the Design

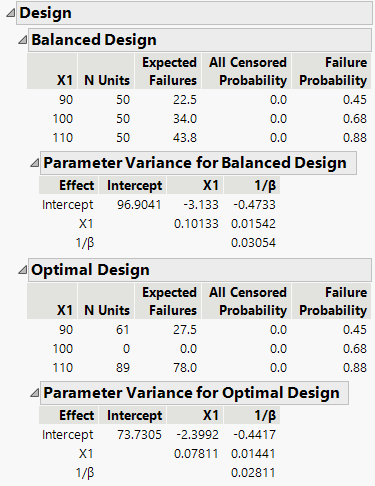

The design report contains a balanced design in addition to the optimal design. The optimal design allocates units to provide the best estimates of failure rates. Compare the variance estimates of the two designs to evaluate the trade off of using a logistically more complex optimal design to the balanced design.

Figure 28.4 ALT Design Sections

Design

Shows tables for both a balanced and the optimal design. For a single factor, the first column gives the levels of the factor. For two factors, the first two columns give the levels of the factors.

N Units

The number of units to be tested at each combination of acceleration levels.

Expected Failures

Expected number of failures for the design setting. The expected number is computed using the prior model specification.

All Censored Probability

Probability that none of the units tested at the combination of acceleration levels fail. The probability is computed using the prior model specification.

Failure Probability

The expected probability of failure for the design settings. The failure probability is calculated as the expected failures divided by the number of units on test.

Note: The expected failures and censoring probabilities enable you to judge whether your prior specifications are reasonable.

Parameter Variance for Balanced Designs

Provides a matrix proportional to the covariance matrix for the estimates of the acceleration model parameters for the balanced design.

Parameter Variance for Optimal Design

Shows a matrix proportional to the covariance matrix for the estimates of the acceleration model parameters for the optimal design. The calculation assumes that the values specified in the Prior Mean section are the true parameter values.

Note: Compare the values in the Parameter Variance for Optimal Design matrix to those in the Parameter Variance for Balanced Design matrix to determine the extent to which the optimal design reduces the variance of estimates.

Review the Design Diagnostics

The design diagnostic report contains optimality criteria, profilers, and a simulator.

Optimality Criteria

Values for three optimality criteria are provided:

D Criterion

D-optimality of the design. See Make D-Optimal Design.

Quantile Criterion

Time I-optimality of the design. See Make Quantile Estimate Optimal.

Probability Criterion

Probability I-optimality of the design. See Make Failure Probability Optimal.

Distribution Profiler

Enables you to explore failure probabilities, based on the optimal design, as you vary the acceleration factors and time. The probabilities are based on the assumption that the values specified in the Prior Mean are the true parameter values.

R Precision Factor (for a 95% CI)

A profiler to evaluate the impact of sample size, level of the factor(s), and the quantile of interest on the R Precision Factor. The R Precision Factor (for a 95% CI) is a measure of the precision of the 95% confidence interval for the quantile of interest.

Simulator

Use the simulator to explore your accelerated model before collecting data.

Number of Simulations

The number of simulation trials to run.

Simulation Probability of Interest

The failure probability of interest.

Simulation Usage

Values for the usage conditions of the acceleration factors.

Run Simulations

Generates a table of summary statistics and a plot of simulated model fits.

Back

Enables you to return to the design specifications to make changes to your design.