Example of a T Chart

In this example, you use the interactive workspace in Control Chart Builder to create a T chart to explore data from a fan manufacturing process. The first column identifies each fan that burned out. The second column identifies the number of hours between each burnout.

T charts are used to measure the time that has elapsed since the last event. See Rare Event Control Charts.

1. Select Help > Sample Data Folder and open Quality Control/Fan Burnout.jmp.

2. Select Analyze > Quality and Process > Control Chart Builder.

3. Drag Hours between Burnouts to the Y role.

4. Drag Burnout to the Subgroup role.

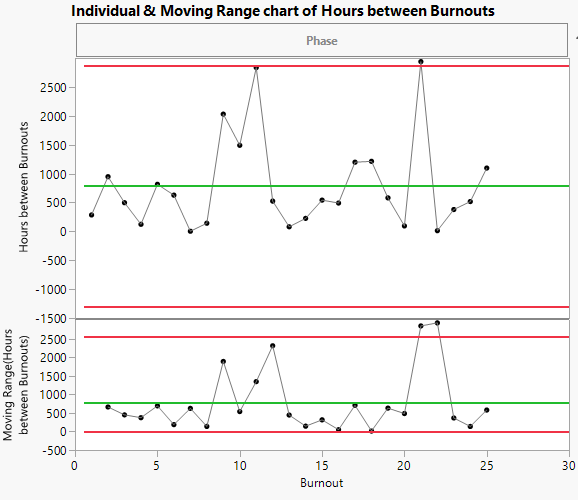

Figure 3.35 Individual and Moving Range Chart of Hours Between Burnouts

5. In the drop-down list, select Rare Event instead of Shewhart Variables.

6. Under Limits, change the Sigma from Negative Binomial to Weibull.

Figure 3.36 T chart of Hours Between Burnouts

In the T chart, all points appear to be within the control limits. It is clear that the Individual & Moving Range chart was inappropriate for the analysis, as the limits were too narrow.