Example of Repeated Measures Degradation

Use the Repeated Measures Degradation platform to model the progression in the length of fatigue-related cracks in test specimens of an alloy. The crack size increases as the alloy endures more cycles. When the crack size reaches 1.6 inches, the alloy is deemed to be unsafe. You are interested in estimating the number of cycles at which 50% of the crack sizes reach 1.6 inches. This example is patterned after an example in Meeker et al. (2022, ch. 21).

1. Select Help > Sample Data Folder and open Reliability/Alloy A.jmp.

2. Select Analyze > Reliability and Survival > Repeated Measures Degradation.

3. Select Length and click Y, Response.

4. Select MCycles and click Time.

5. Select Specimen and click Label, System ID.

6. Type 1.6 in the text box for Upper Failure Definition.

7. Click OK.

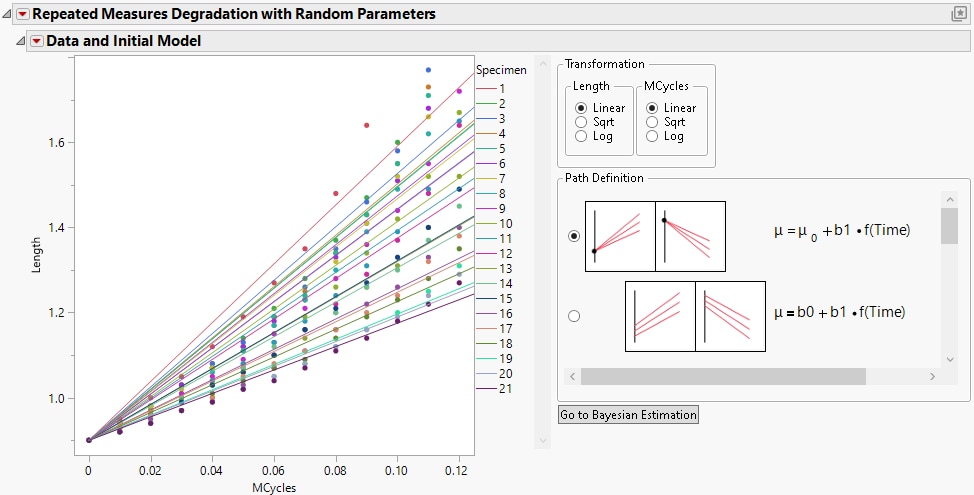

Figure 8.2 Initial Repeated Measures Degradation with Random Parameters Report

The initial report has options to add a transformation to the response (Length) and the time variable (MCycles) and to change the path definition for the model.

8. In the Path Definition panel, scroll down and select the third model.

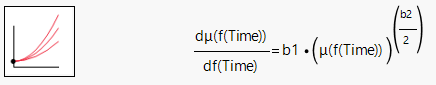

Figure 8.3 Selected Path Definition Model

The curves in the plot update to match the selected model.

9. Click Go to Bayesian Estimation.

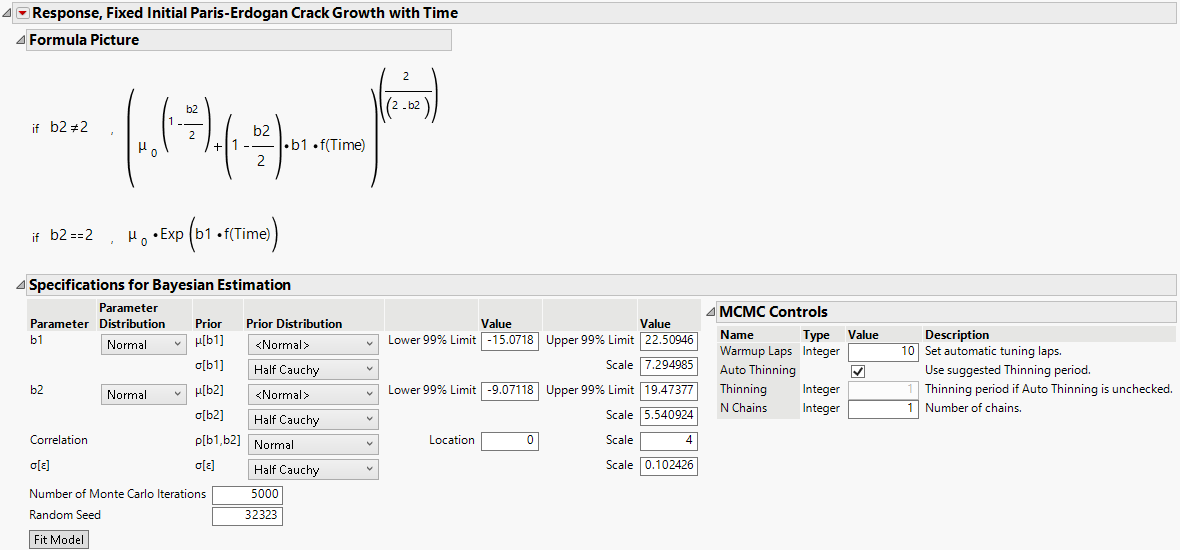

Figure 8.4 Initial Response Report

The initial response report contains a picture of the path definition formula and a panel for specifying priors for the hierarchical Bayes model. There are also options to control the Bayesian estimation procedure.

10. Click Fit Model.

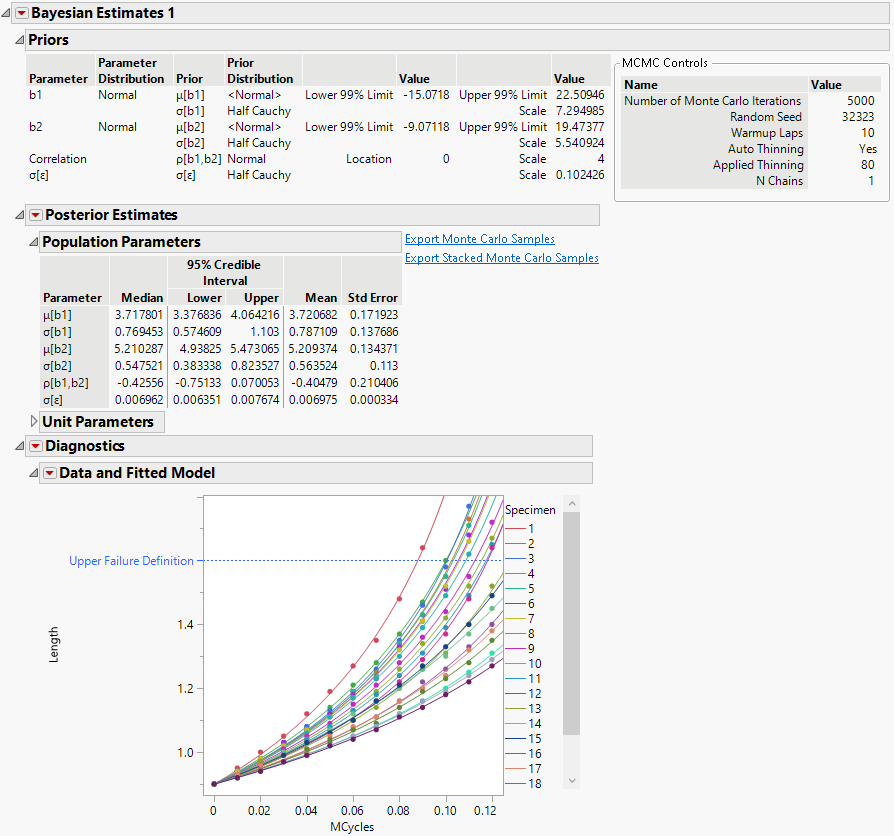

Figure 8.5 Bayesian Estimates Report (Partial)

The Posterior Estimates report shows the results of the Markov chain Monte Carlo (MCMC) procedure. Use the buttons to the right of the table to view all the MCMC samples in a data table. The Diagnostics report shows the original data values along with curves for the fitted model.

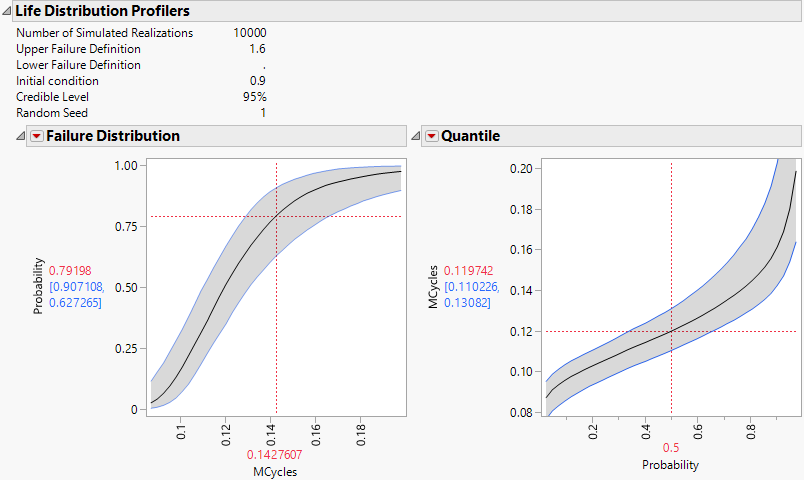

Use the Life Distribution Profilers report to estimate the number of cycles at which 50% of the crack sizes reach 1.6 inches.

11. In the Quantile profiler, type 0.50 for Probability.

Figure 8.6 Life Distribution Profilers

Note the Upper Failure Definition of 1.6 inches. This is the definition of a failure used in the Failure Distribution and Quantile profilers in the Life Distribution Profilers report. The Quantile profiler, at probability 0.50, shows that the estimated number of cycles at which 50% of the crack sizes reach 1.6 inches is 0.1197 with a 95% credible interval of 0.11 to 0.131.