Example of the Process Capability Platform with Normal Variables

In this example, you use the Process Capability platform to analyze standard measurements that a semiconductor manufacturer might make on a wafer as it is being processed. Specification limits for the variables have been entered in the data table through the Column Properties > Spec Limits property.

1. Select Help > Sample Data Folder and open Semiconductor Capability.jmp.

2. Select Analyze > Quality and Process > Process Capability.

3. Click the white triangle next to Processes to view all of the continuous variables.

4. Select PNP1, PNP2, NPN2, PNP3, IVP1, PNP4, NPN3, and IVP2, and click Y, Process.

5. Click OK.

6. Click the Goal Plot red triangle and select Label Overall Sigma Points.

7. Click the Capability Index Plot red triangle and select Label Overall Sigma Points.

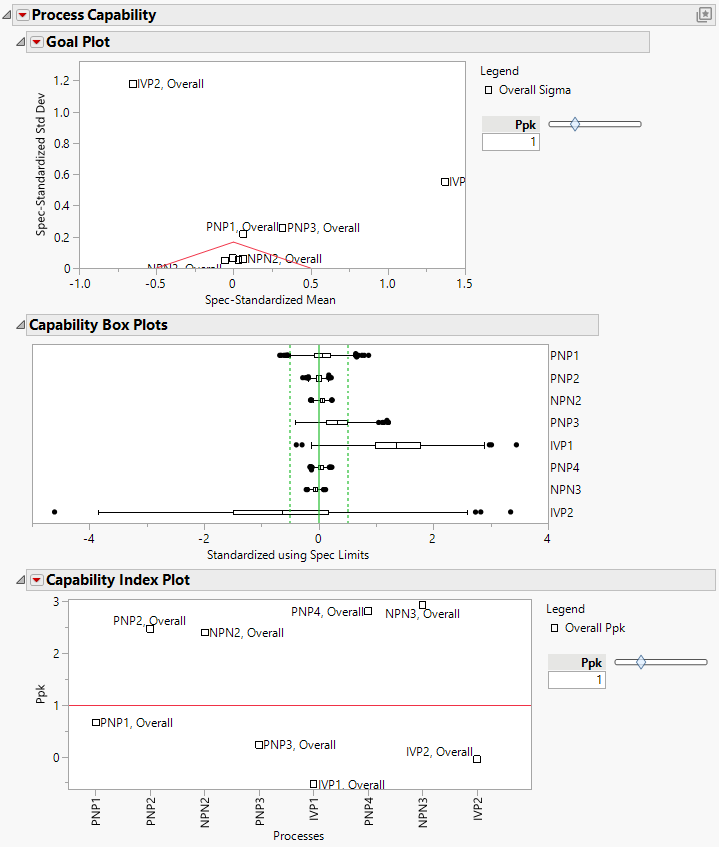

Figure 9.2 Example Results for Semiconductor Capability.jmp

The Goal Plot shows the spec-normalized mean shift on the x-axis and the spec-normalized standard deviation on the y-axis for each variable. The triangular region defined by the red lines in the bottom center of the plot is the goal triangle. It defines a region of capability index values. You can adjust the goal triangle using the Ppk slider to the right of the plot. When the slider is set to 1, note that PNP1, PNP3, IVP1, and IVP2 are outside of the goal triangle and possibly out of specification.

The Capability Box Plots report shows a box plot for each variable in the analysis. The values for each column are centered by their target value and scaled by the specification range. In this example, all process variables have both upper and lower specification limits, and these are symmetric about the target value. It follows that the solid green line shows where the target should be and the dashed lines represent the specification limits.

It appears that the majority of points for IVP1 are above its upper specification limit (USL), and the majority of points for IVP2 are less than its target. PNP2 seems to be on target with all data values inside the specification limits.

The Capability Index Plot plots the Ppk values for each variable. Four variables come from very capable processes, with Ppk values of 2 or more. Four variables have Ppk values below 1.