Mixture Design with Nonmixture Factors

Use the Custom Design platform to create a design for an experiment involving both mixture factors and process factors. The design is an 18-run design that is balanced with respect to the levels of a categorical factor. The design enables you to fit a full response surface.

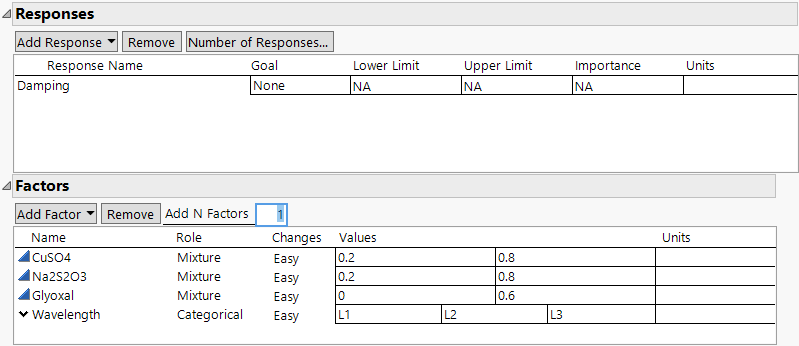

The design consists of a single response, three mixture factors, and a non-mixture factor:

• The response is Damping, which measures the electromagnetic damping of an acrylonitrile powder.

• The three mixture ingredients are:

– CuSO4 (copper sulphate), ranging from 0.2 to 0.8

– Na2S2O3 (sodium thiosulphate), ranging from 0.2 to 0.8

– Glyoxal (glyoxal), ranging from 0 to 0.6

• The nonmixture environmental factor of interest is Wavelength (the wavelength of an electromagnetic wave) at three levels denoted L1, L2, and L3.

Wavelength is a continuous variable. However, the researchers were interested only in predictions at three specific wavelengths. For this reason, you treat Wavelength as a categorical factor with three levels.

There are two parts to this example:

Create the Design

1. Select DOE > Custom Design.

2. Double-click Y under Response Name and type Damping.

3. Click Maximize under Goal and change it to None.

The goal is set to None because the authors of the study do not mention how much damping is desirable.Select Help > Sample Data Folder and open Design Experiment/Donev Mixture Factors.jmp.

4. Click the Custom Design red triangle and select Load Factors.

This loads the three mixture ingredients and the categorical environmental factor. Note that the bounds on the values of the three mixture factors are also loaded.

Figure 5.48 Responses and Factors

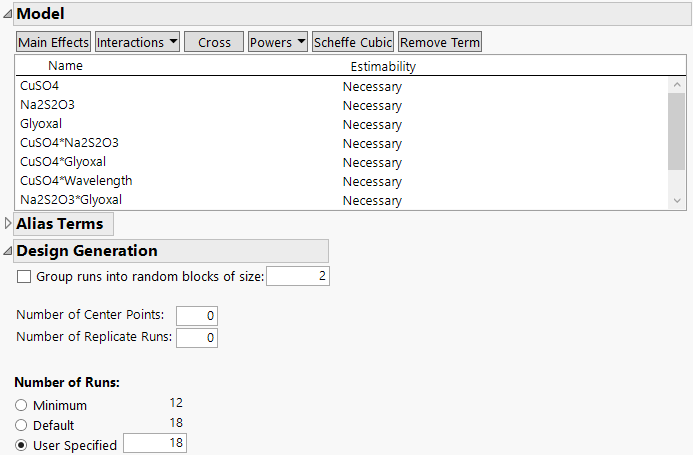

5. In the Model section, click Interactions > 2nd.

An informational JMP Alert window reminds you that JMP removes the main effect terms for non-mixture factors that interact with all the mixture factors. This means that the main effect of Wavelength is removed, but all two-way interactions of mixture factors with Wavelength are added.

6. Click OK to dismiss the message.

The effects in the Model section define a response surface model in the mixture ingredients along with the additive effect of the wavelength. See Scheffé (1958).

Figure 5.49 Model and Design Generation

7. Leave the number of runs at 18.

The choice of 18 runs allows six runs for each of the three levels of the wavelength factor.

Note: Setting the Random Seed in step 8 and Number of Starts in step 9 reproduces the exact results shown in this example. In constructing a design on your own, these steps are not necessary.

8. (Optional) Click the Custom Design red triangle, select Set Random Seed, type 12345, and click OK.

9. (Optional) Click the Custom Design red triangle, select Number of Starts, type 5, and click OK.

10. Click Make Design.

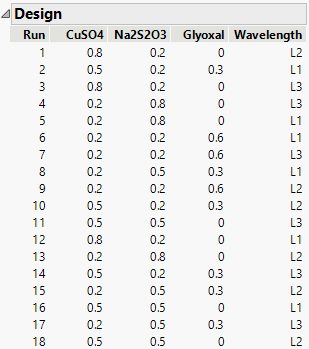

Figure 5.50 18-Run Design

You can check that there are six runs for each level of Wavelength.

Evaluate the Design

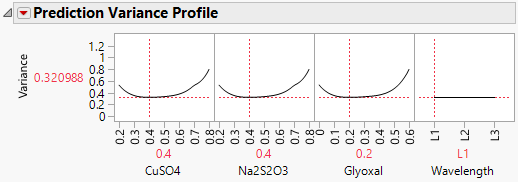

1. Open the Design Evaluation > Prediction Variance Profile section.

Figure 5.51 Prediction Variance Profile for 18-Run Design

Move the slider for Wavelength to verify that the relative prediction variance profiles for the mixture factors do not change across the levels of Wavelength. Move the slider for any one of the mixture factors. The sliders for the other two mixture factors adjust to make the mixture ingredients sum to one. Notice that the smallest relative prediction variances occur near the center settings for the mixture factors.

2. Click the Prediction Variance Profile red triangle and select Maximize Variance.

Notice that the maximum relative prediction variance over the design space is 0.8 times the error variance.

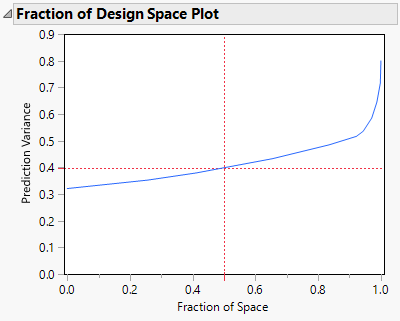

3. Open the Fraction of Design Space Plot section.

Figure 5.52 Fraction of Design Space Plot for 18-Run Design

Over the entire design space, the relative prediction variance is below 0.8. The minimum relative prediction variance is about 0.32. As seen in Figure 5.51, the minimum occurs near the center settings for the mixture factors.

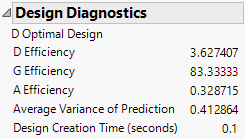

4. Open the Design Diagnostics section.

Figure 5.53 Design Diagnostics for 18-Run Design

The design is optimal relative to the D-optimality criterion, even though its D-efficiency is very low (3.6%). Because mixture designs are far from orthogonal due to the mixture constraint, they typically have very low D-efficiencies. The Average (relative) Variance of Prediction is 0.412864. This is consistent with the Fraction of Design Space plot in Figure 5.52.