Mixture of Mixtures Design

Use the Custom Design platform to construct a design for a mixture of mixtures.

Consider the ingredients that go into a cake. Dry ingredients include flour, sugar, and cocoa. Wet ingredients include milk, melted butter, and eggs. The wet and dry components of the cake are two mixtures that are first mixed separately and then blended together. Table 5.1 lists the factors and the ranges over which you vary them as part of your experiment.

|

Mixture |

Ingredient |

Lower and Upper Levels |

|---|---|---|

|

Dry |

Cocoa |

0.1 - 0.2 |

|

Sugar |

0 - 0.15 |

|

|

Flour |

0.2 - 0.3 |

|

|

Wet |

Butter |

0.1 - 0.2 |

|

Milk |

0.25 - 0.35 |

|

|

Eggs |

0.05 - 0.20 |

The dry components (the mixture of cocoa, sugar, and flour) comprise 45% of the combined mixture. The wet components (butter, milk, and eggs) comprise 55%.

Note: With the constraints on the dry and wet ingredients, if you include all 6 factors in the mixture model, a model singularity exists.

The goal of your experiment is to optimize a Taste rating. Taste is rated on a scale of 1 to 10, with 10 representing the best taste.

You construct a 10-run design to fit a main effects model. Because of the constraint on the proportions of dry and wet ingredients, you need to include only five factors in the Model section to avoid singularity. The choice of which factor not to include is arbitrary.

This example contains two parts:

• Analyze the Experimental Results

Create the Design

1. Select DOE > Custom Design.

2. Double-click Y under Response Name and type Taste.

Note that the default goal is Maximize. Because you want to maximize the Taste rating, do not change the goal.

3. Click under Lower Limit and type 0.

The least desirable rating is 0.

4. Click under Upper Limit and type 10.

The most desirable rating is 10.

5. Leave the area under Importance blank.

Because there is only one response, that response is given Importance 1 by default.

6. Select Help > Sample Data Folder and open Design Experiment/Cake Factors.jmp.

7. Click the Custom Design red triangle and select Load Factors.

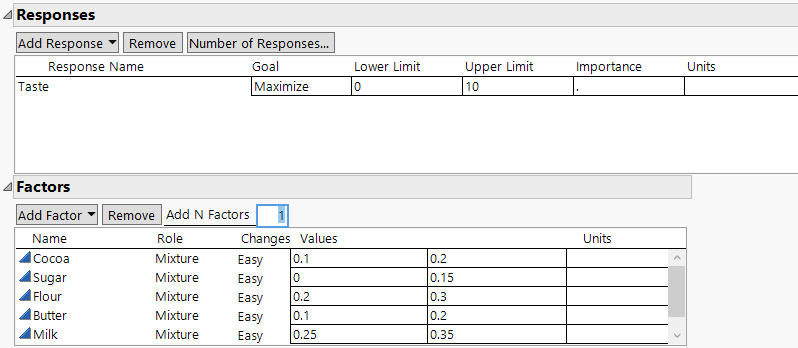

Figure 5.54 Completed Responses and Factors

Note that the factors are all mixture factors. The Values that define the range of settings for the experiment vary from factor to factor.

8. In the Define Factor Constraints section, select Specify Linear Constraints.

9. In the Linear Constraints panel, click Add twice.

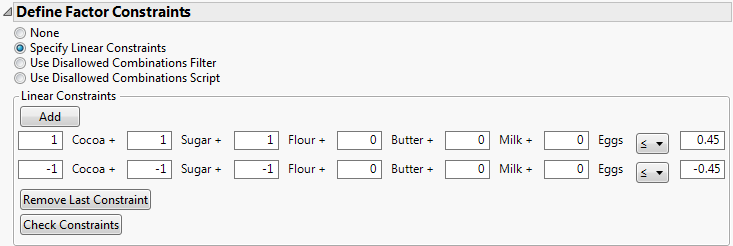

10. Enter the constraints shown in Figure 5.55.

Figure 5.55 Define Factor Constraints

Note that the second constraint is equivalent to specifying that the sum of Cocoa, Sugar, and Flour is greater than or equal to 0.45. The two constraints together imply that Cocoa, Sugar, and Flour comprise exactly 45% of the mixture, ensuring that the wet factors constitute the remaining 55%.

11. In the Model section, select Eggs and click Remove Term.

Because of the equality constraint, a model containing all six effects would be singular.

12. Type 10 next to User Specified.

Your experiment requires baking 10 cakes.

Note: Setting the Random Seed in step 13 and Number of Starts in step 14 reproduces the results shown in this example. In constructing a design on your own, these steps are not necessary.

13. (Optional) Click the Custom Design red triangle, select Set Random Seed, type 12345, and click OK.

14. (Optional) Click the Custom Design red triangle, select Number of Starts, type 40, and click OK.

15. Click Make Design.

A JMP Alert informs you that your factor constraints include an equality constraint. This was what you intended, because the sum of the dry ingredient proportions is constrained to 45%.

16. Click OK to dismiss the JMP Alert.

17. Click Make Table.

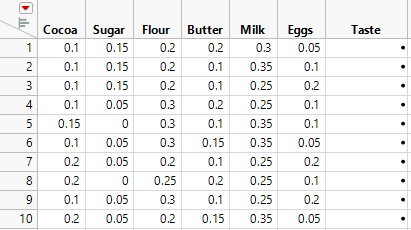

Figure 5.56 Mixture of Mixtures Design

The settings for the dry ingredients, Cocoa, Sugar, and Flour, sum to 45% of the mixture and the settings for the wet ingredients, Butter, Milk, and Eggs, sum to 55% of the mixture. The settings also conform to the upper and lower limits given in the Factors section.

Analyze the Experimental Results

The Cake Data.jmp sample data table shows the results of the experiment. The design table contains a Model script that opens a Fit Model window showing the five main effects specified in the DOE window’s Model section. Notice that the main effect of Eggs is not included in the Model section for this design. The level of Eggs can be determined by the settings of the other 5 factors and the constraint on the dry ingredients. This script was saved to the data table when it was created by Custom Design.

1. Open the Cake Data.jmp sample data table, located in the Design Experiment folder.

2. In the Table panel of the design table, click the green triangle next to the Model script.

The main effect due to Eggs is not included. To avoid model singularities, the Eggs effect was excluded from the Model section in the Custom Design window. The five effects are designated as Response Surface and Mixture effects.

3. Click Run.

A JMP Alert appears, notifying you that the Profiler cannot be shown because of the mixture of mixtures constraint on the subsets of factors.

4. Click OK to dismiss the JMP Alert.

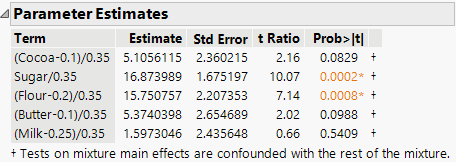

The Parameter Estimates report indicates that Sugar and Flour are significant at the 0.05 level.

Figure 5.57 Parameter Estimates Report