The Type 1 Gauge Study Report

The Type 1 Gauge Study report contains a Type 1 Gauge Analysis report for each measurement column that was specified in the launch window. The column name is included in the title of each analysis report. By default, each Type 1 Gauge Analysis report contains a run chart of measurements and a table of summary and capability statistics.

• Summary and Capability Statistics Table

Run Chart

In the Type 1 Gauge Analysis report, the run chart of measurements includes horizontal lines at the reference value and upper and lower tolerances. The tolerances are based on the reference standard value (Ref), percent of tolerance value (p), and the tolerance range (Tol) and are calculated as follows:

Portion of Tolerance = Ref ± 0.5p*Tol

The Run Chart red triangle menu contains the following options:

Show Portion of Tolerance

Shows or hides the portion of tolerance lines on the run chart. If a tolerance range is given or calculated, the portion of tolerance is shown by default.

Show Reference

Shows or hides the reference value on the run chart. The reference value is shown by default.

Show Mean

Shows or hides the mean on the run chart.

Summary and Capability Statistics Table

In the Type 1 Gauge Analysis report, the Summary and Capability Statistics table contains statistics to determine the repeatability of the measurement system.

Note: Statistics that involve the tolerance range (Tol) are included only if a tolerance range is specified in the MSA metadata prior to the analysis.

Reference (Ref)

The reference standard value defined in the MSA metadata.

Mean

The mean of the observed measurements.

Std Dev

The standard deviation, σ, of the observed measurements.

k*Std Dev

The sigma multiplier, defined in the launch, multiplied by Std Dev.

N

The number of observed measurements.

Tolerance Range (Tol)

The tolerance range.

Ref - (p/2)*Tol

The lower portion of tolerance value that is shown on the Run Chart.

Ref + (p/2)*Tol

The upper portion of tolerance value that is shown on the Run Chart.

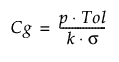

Cg

A measure of how well the variation of the measurements fits into the specified tolerance range. A common threshold for a good measurement system is a Cg value of 1.33 or greater. Cg is calculated as follows:

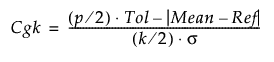

Cgk

A measurement that is similar to the Cg value calculation, but also takes the bias into account. A common threshold for a good measurement system is a Cgk value of 1.33 or greater. Cgk is calculated as follows:

% Var for Repeatability

The percent of the tolerance range that is consumed by kσ. Higher values indicate more measurement variability in the system. The % Var for Repeatability is calculated as follows:

% Var for Repeatability = (p/Cg) × 100

% Var for Repeatability and Bias

A measurement that is similar to the % Var for Repeatability, but also takes the bias into account. The % Var for Repeatability and Bias is calculated as follows:

% Var for Repeatability and Bias = (p/Cgk) × 100

Bias

The difference between the mean and the reference standard value.

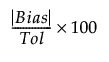

Bias/Tol %

The percent bias value, which is calculated as follows:

Resolution (Res)

The smallest resolution that your measurement device is capable of reporting.

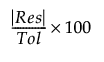

Res/Tol %

The percent resolution value, which is calculated as follows: